- Home

- Products

- Yarn Winding

- Dye Package Winder/Rewinder

- CO-55 Precision Bobbin Winder

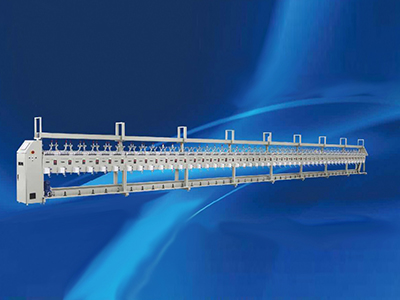

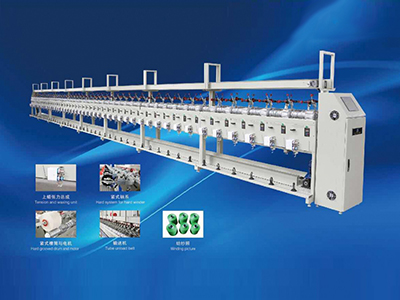

CO-55 Precision Bobbin Winder

Our CO-55 precision bobbin winder is utilized prior to the covering machine or two-for-one twisters. It is suitable for all yarn types.

Every spindle in the winding machine is equipped with a BTSR online tensioner that adjusts the yarn tension to ensure the entire bobbin is wound with uniform tension.

The precision winding machine is able to automatically probe the bobbin height and position without any manual intervention needed. It has a maximum operation speed of 1600 m/min, 3 times faster than a traditional winding machine.

Parameters

| Type of winding | Set a constant spacing between the yarns to achieve precision winding |

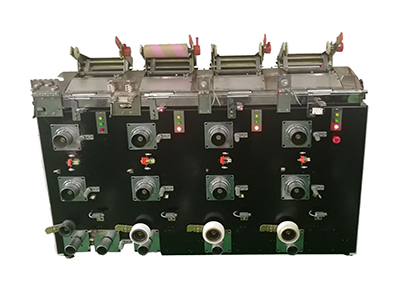

| Control head | Touch screen industrial computer |

| Winding speed | Up to 1,600 m/min |

| Winding space | 0.01-9.99 mm |

| Power consumption per spindle | 40-100 W,varying with processing speed |

| Dimensions of complete machine | 13,060 mm×1,320 mm×1,790 mm |

| Weight of control head | 190 kg |

| Package shape | Side cones or single or double cones |

| Dimensions of section | 2,080mm*1,320mm*1,790mm,dimensions of machine head: 800mm*600mm*1,650mm |

| Thread guide traverse | 25-150mm,the maximum length of edged yarn tube is 150m,the maximum diameter of edged yarn tube is 160m |

| Number of spindles per section | 16 spindles/section-double sided, max. 96 spindles |

| Tension sensor range | 0-25g,0-50g,0-100g,0-250g,choose the yarn according to the variety and specification |

| Theoretical yield of a single spindle in 24 hours | Linear speed×dtex×60×24÷9000/1000 |

| Weight per section | 650 kg |

| Selection of configuration | Oiling device may be added as required |

Inquiry

More Knitting Machines