- Home

- Products

- Yarn Winding

- Dye Package Winder/Rewinder

- CO-60B Precise Winding Machine (Cone to Cone, Automatic Doffing)

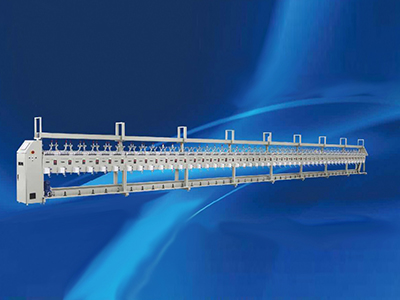

CO-60B Precise Winding Machine (Cone to Cone, Automatic Doffing)

Our CO-60B precise winding machine was developed to wind yarn from cone to cone or hank to cone and separates control by spindle and hard yarn cone, making it suitable for all types of yarn winding. It comes equipped with an overfeeding roller, gate tension device, online tensioner and other components to ensure each cone is wound with constant tension for a higher degree of product quality. This precision winding machine is PLC controlled, easy to operate, and features incredible production efficiency.

Parameters

| Type of winding | Digital/Precision winding |

| Control head | Industrial computer with touch screen |

| Yarn-guiding speed | The number of shuttles is up to 1,000 times/min |

| Number of spindles | Min. 4 spindles/ Max.60 spindles |

| Yarn count | 5-4,500 dtex |

| Dimensions of complete machine | 22,450 mm×1,153 mm×1,855 mm |

| Weight of control head | 190 kg |

| Type of winding | Parallel tube,min. diameter 30 mm,max. diameter 100 mm,max. length 230 mm |

| Yield of a single spindle in 24 hours | Linear speed×dtex×24×60÷9000/1000 |

| Winding spindles | Electronic yarn guide and line winding system, auto-drive, etc. |

| Yarn-guiding speed | Up to 1100 m/min |

| Number of spindles per section | 4 spindles |

| Take-up bobbin diameter | Max. 160 mm |

| Power consumption per spindle | 120 W |

| Weight of each machine | 650 kg |

| Automatic winder | Installed according to requirements |

Inquiry

More Knitting Machines